Galvanized Razor Wire Diameter,Blade Types,Blade Thickness

Galvanized razor wire refers to razor wire that has undergone a galvanization process to protect it from corrosion, making it more durable and suitable for outdoor use, especially in environments exposed to moisture. The galvanization typically involves coating the wire with a layer of zinc.

Galvanized razor wire Diameter,Blade Types,Blade Thickness,Loops per Coil

Specifications:

- Diameter: Common diameters can range from 450mm to 1000mm for concertina coils, though other sizes are also available based on the design and requirement.

- Blade Types: There are various blade profiles, such as BTO-10, BTO-22, CBT-60, CBT-65, and others, which specify the design, length, width, and spacing of the barbs.

- Blade Thickness: Typically ranges between 0.4mm to 0.6mm.

- Loops per Coil: The number of loops in each coil can vary, with common numbers being 33, 56, or more, depending on diameter and design.

- Clip Count: The spirals can be clipped together for added strength, often using 3 or 5 clips per loop.

Material:

- Core Wire Material: The central wire that gives the razor wire its structure is usually made of steel.

- Blade Material: The razor blades are also crafted from steel.

- Galvanization: The steel wire and blades undergo a galvanization process where they're coated with a protective layer of zinc. There are two primary methods:

- Hot-Dipped Galvanization: The wire is immersed in molten zinc, resulting in a thick, durable coating.

- Electro-Galvanization: The wire is electroplated with zinc, resulting in a thinner coating compared to hot-dipped galvanization.

The hot-dipped galvanization process typically provides a thicker zinc coating and offers superior corrosion resistance compared to electro-galvanization.

When purchasing or specifying galvanized razor wire, it's crucial to consider the environment where it will be used. In highly corrosive environments or coastal areas with salty air, a thicker zinc coating or even stainless steel might be more appropriate.

Galvanized razor wire consists of hot-dip galvanized sheets and hot-dip galvanized steel wire. The zinc coating forms a protective barrier that helps prevent rust and corrosion and extends the service life of the razor wire.

The galvanized coating provides several benefits for razor wire:

Corrosion resistance: The zinc coating acts as a sacrificial layer, protecting the underlying steel from corrosion and rust. This extends the lifespan of the razor wire and ensures its effectiveness over time.

Enhanced durability: Galvanized razor wire is more resistant to scratches, abrasion, and physical damage compared to non-galvanized wire. It can withstand impact and maintain its sharpness and integrity for a longer period.

Cost-effective: Galvanized razor wire requires less maintenance and replacement, resulting in lower long-term costs. The galvanized coating provides a protective barrier, reducing the need for frequent repairs or replacements.

Versatility: Galvanized razor wire can be used in various security applications, such as prisons, military installations, border fences, and high-security areas. It is suitable for both temporary and permanent installations, offering flexibility in different security scenarios.

Electro-Galvanization Razor Wire Roll

Hot-Dipped Galvanization Razor Wire

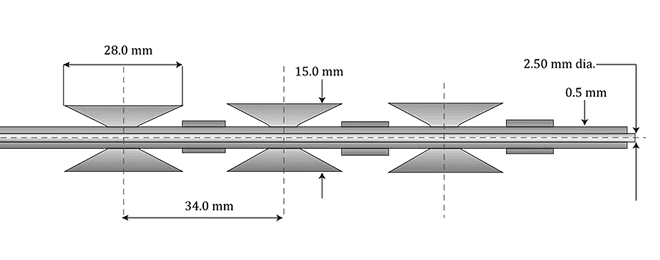

| Type | Drawings | Thickness (mm) | Length (mm) | Width (mm) | Spacing (mm) | Core Wire Diameter (mm) |

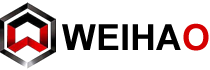

| CBT-60 |  | 0.5 ± 0.05 | 60.0 ± 2 | 31 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

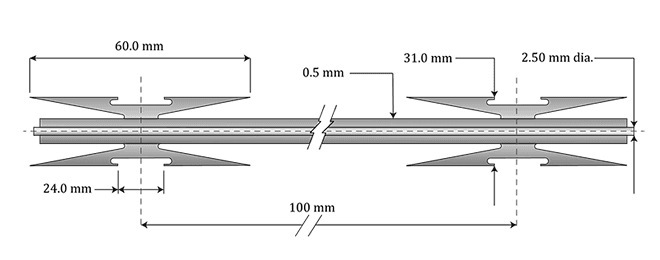

| CBT-65 |  | 0.5 ± 0.05 | 65 ± 2 | 21 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

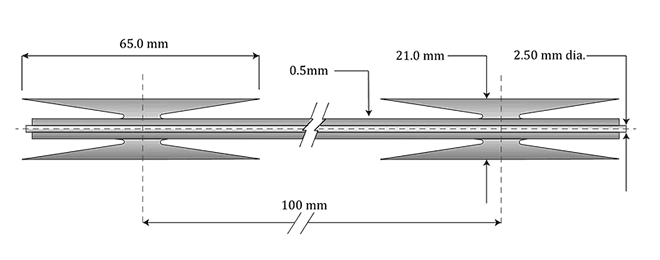

| BTO-30 |  | 0.5 ± 0.05 | 30 ± 1 | 18 ± 1 | 45 ± 2 | 2.5 ± 0.1 |

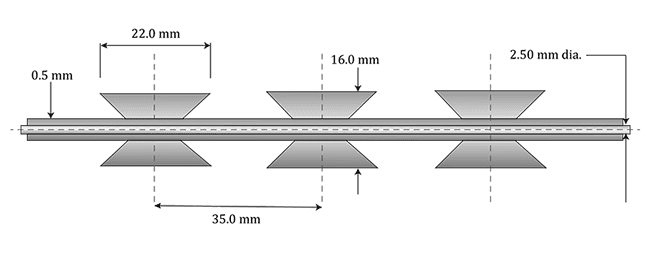

| BTO-22 |  | 0.5 ± 0.05 | 22 ± 1 | 16 ± 1 | 35 ± 1 | 2.5 ± 0.1 |

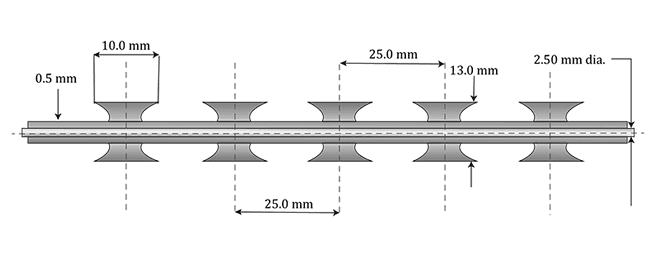

| BTO-10 |  | 0.5 ± 0.05 | 10 ± 1 | 13 ± 1 | 25 ± 1 | 2.5 ± 0.1 |

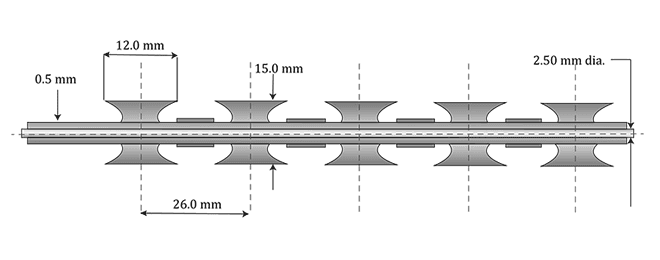

| BTO-12 |  | 0.5 ± 0.05 | 12 ± 1 | 15 ± 1 | 26 ± 1 | 2.5 ± 0.1 |

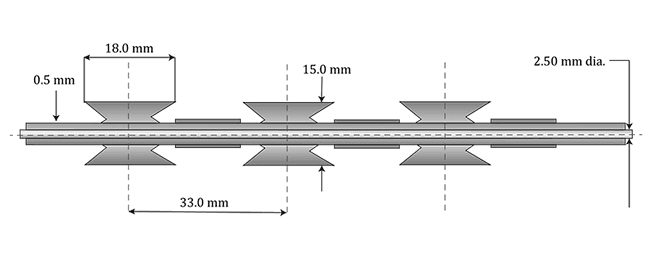

| BTO-18 |  | 0.5 ± 0.05 | 18 ± 1 | 15 ± 1 | 33 ± 1 | 2.5 ± 0.1 |

| BTO-28 |  | 0.5 ± 0.05 | 28 ± 1 | 15 ± 1 | 45 ± 1 | 2.5 ± 0.1 |

Coil Loop Specifications

| Outer Diameter | Loops | Extended Length | Blade Type | Note |

| 300 mm | 33 | 4–6 m | CBT- 60, 65 | Single coil |

| 450 mm | 33 | 7–8 m | CBT- 60, 65 | Single coil |

| 500 mm | 56 | 12–13 m | CBT- 60, 65 | Single coil |

| 700 mm | 56 | 13–14 m | CBT- 60, 65 | Single coil |

| 960 mm | 56 | 14–15 m | CBT- 60, 65 | Single coil |

| 450 mm | 56 | 8–9 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 500 mm | 56 | 9–10 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 600 mm | 56 | 10–11 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 700 mm | 56 | 10–12 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 800 mm | 56 | 11–13 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 900 mm | 56 | 12–14 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 980 mm | 56 | 14–16 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |