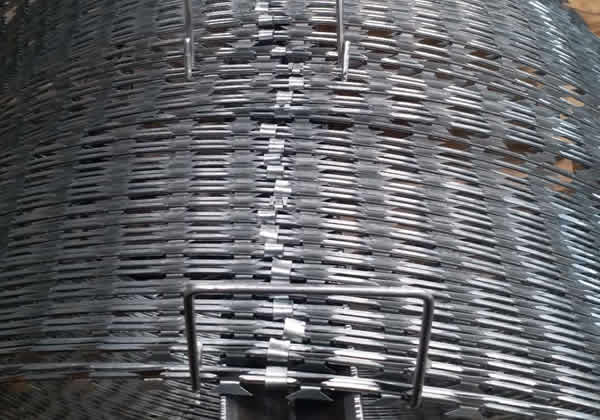

Razor Wire Processing with Hot-dip Galvanized Steel or Stainless Steel Plates

At Weihao Co., as manufacturers and exporters of razor barbed wire, we adhere to a stringent production process that ensures our products stand apart in terms of quality and durability. Our extensive production journey begins with the meticulous preparation of raw materials and spans through precision blade processing, expert rope braiding, and careful blade installation, followed by thorough quality inspections and apt packaging and storage for the finished product.

1,Raw Material Preparation:

The foundation of our razor wire lies in the high-grade materials used, primarily comprising blades and ropes. Our blades are fabricated from high-strength alloy steel which boasts a sharp edge and robust back, ensuring maximum efficacy. On the other hand, our ropes are woven from high-strength, wear-resistant synthetic fibers such as polyester, nylon, or high-density polyethylene, guaranteeing durability and a strong hold.

2,Blade Processing:

Our blades undergo a meticulous processing journey to meet the high standards set forth. Beginning with hot-dip galvanized steel or stainless steel plates, we employ punch presses to stamp out blades in the form of strips, available in various configurations like 7, 9, 11, 23, and 27 strips, all in singular formation. This stage involves precise cutting, grinding, and heat treatment to enhance the blades' sharpness, smooth back, hardness, and wear resistance.

3,Rope Woven Braiding:

Rope braiding is a crucial phase in our production process, where we employ advanced braiding machines to interweave, stretch, and compress the rope materials, crafting a strong, flexible rope that forms the backbone of our razor wire products.

4, Blade Installation:

The synergy between the blade and rope is established in this phase. Our experts meticulously position the blades on the ropes and utilize specialized tools to ensure a firm, reliable connection. Attention to the direction and angle of the blade is crucial to ascertain the razor wire will serve its deterrent purpose efficiently.

5,Quality Inspection:

Post-production, our razor wires are subjected to rigorous quality checks. This encompasses assessing the appearance, blade sharpness, and the robustness of the blade-rope connection. Our stringent inspection protocols ensure that every piece of razor wire adheres to the industry standards, ready to meet the demands of our global clientele.

6,Packaging and Storage:

Upon passing the quality checks, our razor barbed wires are securely packaged using cardboard boxes or plastic bags to prevent any damage during transit or storage. We also ensure optimal storage conditions, avoiding direct sunlight and high temperature, to uphold the quality and prolong the lifespan of our razor wire products.

Our commitment to excellence at every stage of the razor wire production process underscores the trust and reliability synonymous with Weihao Co.