Stainless Steel Concertina Wire Material,Applications and Cost

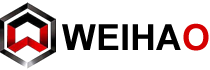

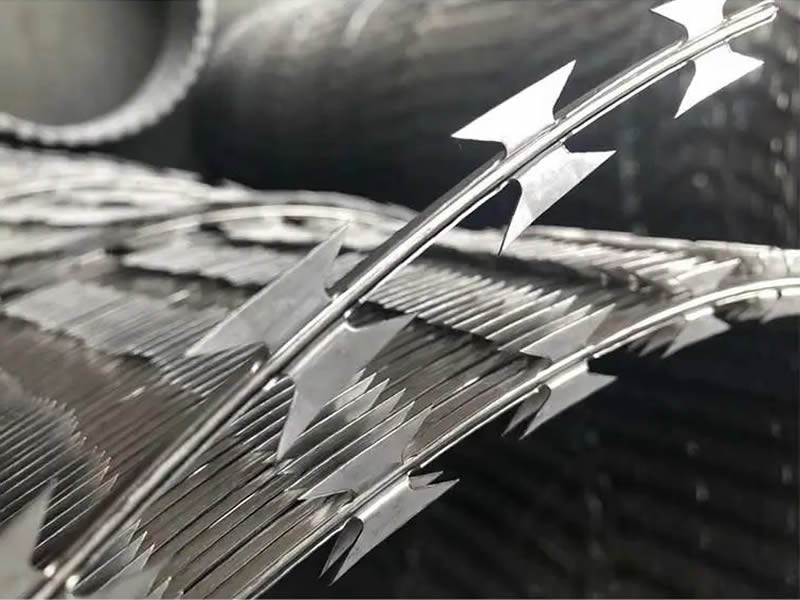

Stainless steel concertina wire refers to a type of high-security perimeter fencing material that is made from stainless steel wire and features a concertina coil design. It is designed to create a formidable physical barrier that is difficult to breach, acting as a strong deterrent against unauthorized access and intrusions.

-

Material: It is made from stainless steel, which provides superior resistance to corrosion, especially when compared to regular steel or even galvanized steel.

-

Design: The concertina wire is characterized by its spiral coils, which can be expanded and stretched. These coils have sharp razor blades or barbs at regular intervals, making the wire a formidable barrier.

-

Applications: Due to its high-security features, stainless steel concertina wire is commonly used in places requiring robust perimeter protection, such as military installations, prisons, airports, border fences, and other high-security zones.

-

Durability: Stainless steel's inherent resistance to environmental factors means that this type of concertina wire will have a longer lifespan and require less maintenance in most conditions compared to its non-stainless counterparts.

-

Cost: Stainless steel concertina wire is typically more expensive than galvanized concertina wire due to the material's increased durability and resistance properties.

-

Varieties: Within stainless steel grades, there are variations (e.g., 304, 316) that offer different levels of corrosion resistance. The specific environment (e.g., coastal areas with salty air) can dictate which grade is most appropriate.

Stainless steel concertina wire offers several advantages:

Corrosion resistance: Stainless steel is known for its excellent corrosion resistance properties. This makes stainless steel concertina wire highly durable and suitable for use in outdoor environments, even in coastal or humid areas.

Longevity: The use of stainless steel wire ensures the longevity of the concertina wire. Stainless steel is resistant to rust and deterioration, allowing the wire to maintain its strength and effectiveness over time.

High tensile strength: Stainless steel wire has high tensile strength, making it difficult to cut or break through. This adds an extra layer of security to the fencing system.

Low maintenance: Stainless steel concertina wire requires minimal maintenance. It does not require regular painting or coating to maintain its corrosion resistance, resulting in cost savings and reduced maintenance efforts.

Aesthetically pleasing: Stainless steel concertina wire offers a sleek and modern appearance, making it suitable for various applications where aesthetics are important.

Stainless steel concertina wire is commonly used in high-security areas such as military installations, prisons, airports, and critical infrastructure facilities. It provides an effective and durable solution for enhancing perimeter security and preventing unauthorized access.

BTO-22 Stainless Steel Concertina Wire

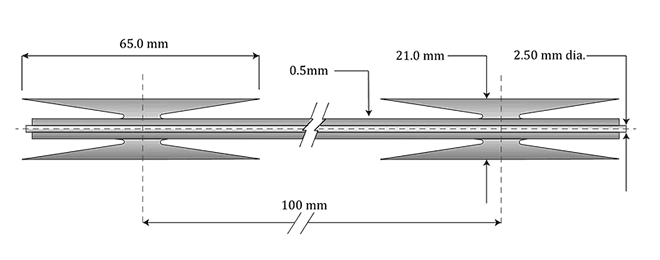

CBT-65 Stainless Steel Concertina Wire

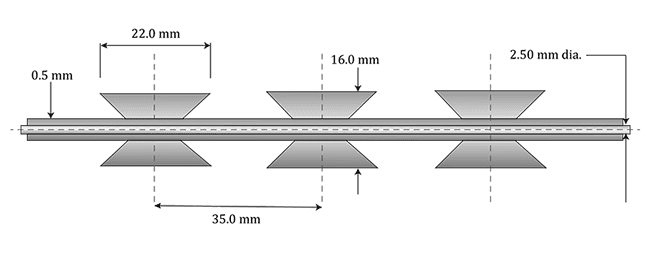

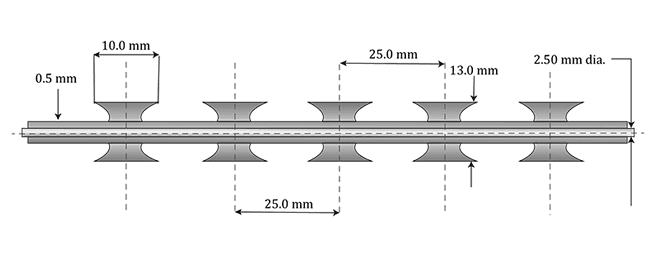

BTO-10 Stainless Steel Concertina Wire

Stainless Steel Concertina Wire Packaging

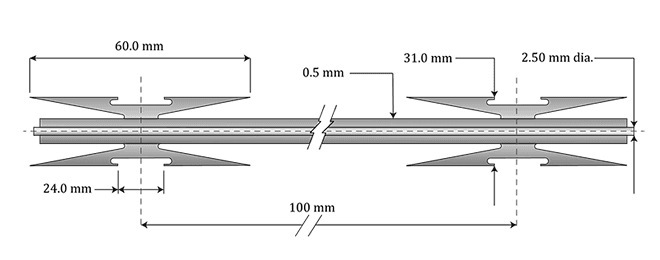

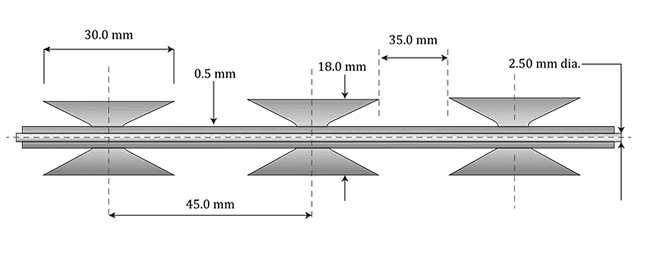

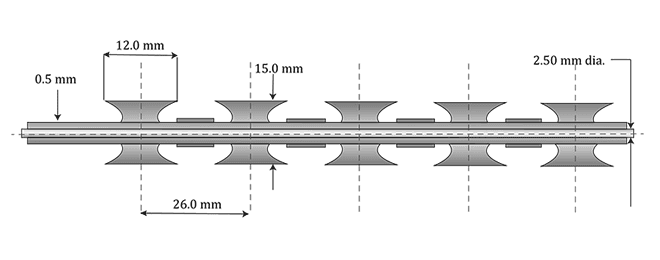

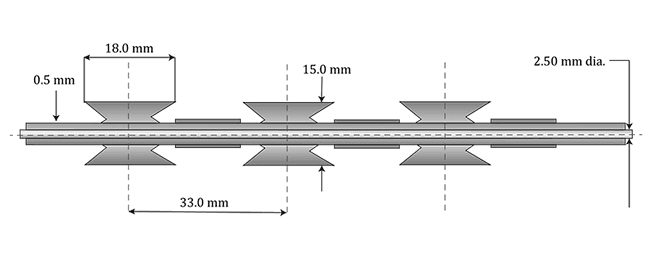

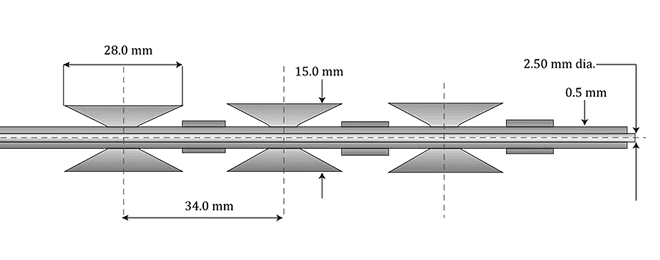

| Type | Drawings | Thickness (mm) | Length (mm) | Width (mm) | Spacing (mm) | Core Wire Diameter (mm) |

| CBT-60 |  | 0.5 ± 0.05 | 60.0 ± 2 | 31 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

| CBT-65 |  | 0.5 ± 0.05 | 65 ± 2 | 21 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

| BTO-30 |  | 0.5 ± 0.05 | 30 ± 1 | 18 ± 1 | 45 ± 2 | 2.5 ± 0.1 |

| BTO-22 |  | 0.5 ± 0.05 | 22 ± 1 | 16 ± 1 | 35 ± 1 | 2.5 ± 0.1 |

| BTO-10 |  | 0.5 ± 0.05 | 10 ± 1 | 13 ± 1 | 25 ± 1 | 2.5 ± 0.1 |

| BTO-12 |  | 0.5 ± 0.05 | 12 ± 1 | 15 ± 1 | 26 ± 1 | 2.5 ± 0.1 |

| BTO-18 |  | 0.5 ± 0.05 | 18 ± 1 | 15 ± 1 | 33 ± 1 | 2.5 ± 0.1 |

| BTO-28 |  | 0.5 ± 0.05 | 28 ± 1 | 15 ± 1 | 45 ± 1 | 2.5 ± 0.1 |

Coil Loop Specifications

| Outer Diameter | Loops | Extended Length | Blade Type | Note |

| 300 mm | 33 | 4–6 m | CBT- 60, 65 | Single coil |

| 450 mm | 33 | 7–8 m | CBT- 60, 65 | Single coil |

| 500 mm | 56 | 12–13 m | CBT- 60, 65 | Single coil |

| 700 mm | 56 | 13–14 m | CBT- 60, 65 | Single coil |

| 960 mm | 56 | 14–15 m | CBT- 60, 65 | Single coil |

| 450 mm | 56 | 8–9 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 500 mm | 56 | 9–10 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 600 mm | 56 | 10–11 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 700 mm | 56 | 10–12 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 800 mm | 56 | 11–13 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 900 mm | 56 | 12–14 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 980 mm | 56 | 14–16 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |