Razor Wire also known as Barbed Tape High-Security Fencing

Razor wire, often used as a security measure, is a type of fencing wire made of sharp-edged metal strips combined with a wire core. Let's delve into the materials commonly used for razor wire and its general specifications:

Material:

-

Core Wire Material: The inner core wire, which provides strength and structure to the razor wire, is commonly made from:

- Galvanized Steel: This is steel coated with zinc to prevent rusting and corrosion.

- Stainless Steel: This offers higher resistance to rust and corrosion, especially in harsh environments.

- Blade Material: The razor blades, which give the wire its sharpness, are typically made from the same materials as the core (galvanized steel or stainless steel) to ensure uniform corrosion resistance.

Specifications:

-

Diameter: The overall diameter of coiled razor wire can range widely based on its application, from 450mm to 1000mm or more.

-

Blade Types/Profiles: There are various blade designs with specific characteristics. Common profiles include BTO-10, BTO-22, CBT-60, CBT-65, and others. Each type denotes different blade dimensions and spacings.

-

Blade Thickness: Generally, the thickness of the blade might range from 0.4mm to 0.6mm, but this can vary.

-

Wire Diameter: This refers to the diameter of the core wire and can range from 2.0mm to 3.0mm or more.

-

Spacing between Blades: This can vary, but common spacings might be around 26mm to 100mm.

-

Coil Loops: Depending on the diameter and design, a coil can have a specific number of loops, commonly 33, 56, or more.

-

Clips: Spirals of razor wire can be clipped together at intervals to make it more difficult to spread apart. The number of clips per loop can vary.

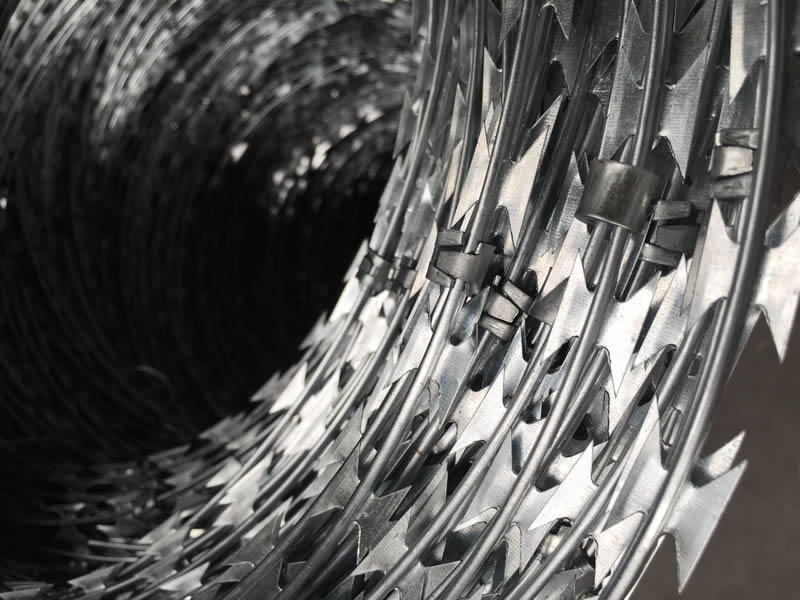

Razor wire is available in various forms, such as concertina coils, flat wrap coils, and straight line razor wire. When specifying or purchasing razor wire, one should consider the intended application, desired security level, and environmental conditions to select the most appropriate material and specifications.

Razor wire is commonly used in military installations, prisons, border security, and other high-security areas where enhanced perimeter protection is required. It is typically installed on fences, walls, or other structures to prevent climbing, cutting, or scaling.

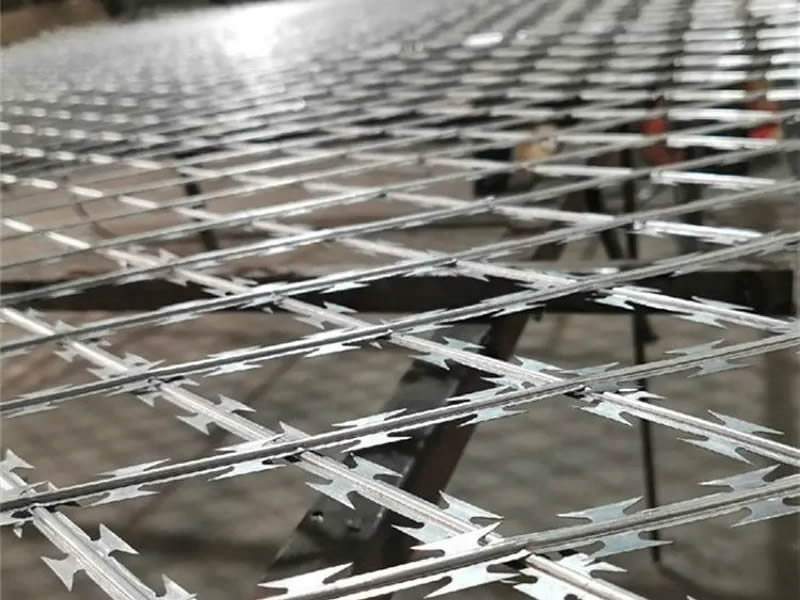

The sharp barbs or razor blades on the wire make it dangerous for individuals to come into contact with, further enhancing its security effectiveness. Razor wire is available in various configurations, such as concertina coils, flat wrap, or welded mesh panels, allowing for flexibility in installation based on specific security requirements and site conditions.

Stainless Steel Razor Wire

Galvanized Razor Wire

Welded Razor Wire

Galvanized Concertina Razor Wire

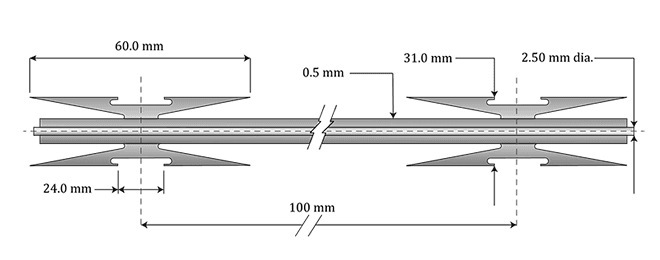

| Type | Drawings | Thickness (mm) | Length (mm) | Width (mm) | Spacing (mm) | Core Wire Diameter (mm) |

| CBT-60 |  | 0.5 ± 0.05 | 60.0 ± 2 | 31 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

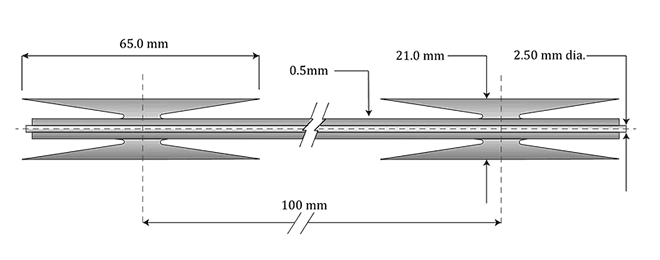

| CBT-65 |  | 0.5 ± 0.05 | 65 ± 2 | 21 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

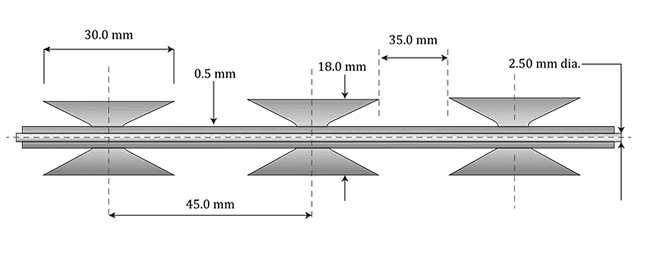

| BTO-30 |  | 0.5 ± 0.05 | 30 ± 1 | 18 ± 1 | 45 ± 2 | 2.5 ± 0.1 |

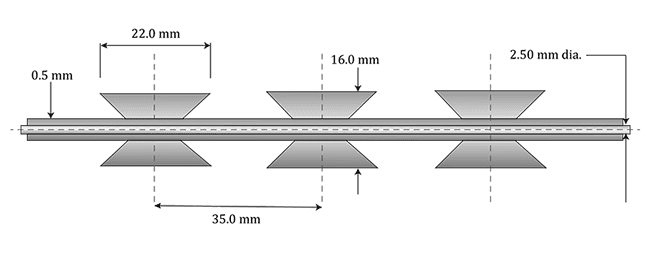

| BTO-22 |  | 0.5 ± 0.05 | 22 ± 1 | 16 ± 1 | 35 ± 1 | 2.5 ± 0.1 |

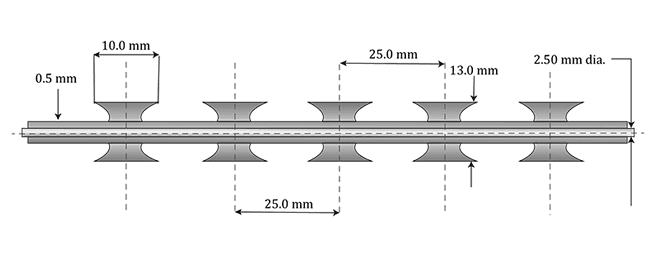

| BTO-10 |  | 0.5 ± 0.05 | 10 ± 1 | 13 ± 1 | 25 ± 1 | 2.5 ± 0.1 |

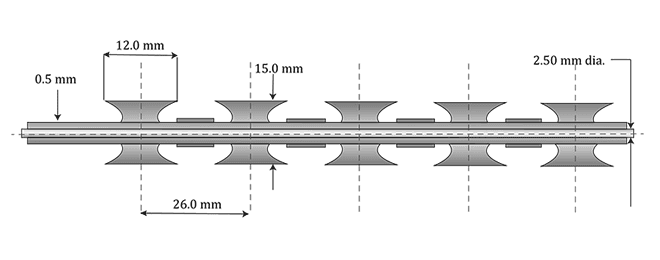

| BTO-12 |  | 0.5 ± 0.05 | 12 ± 1 | 15 ± 1 | 26 ± 1 | 2.5 ± 0.1 |

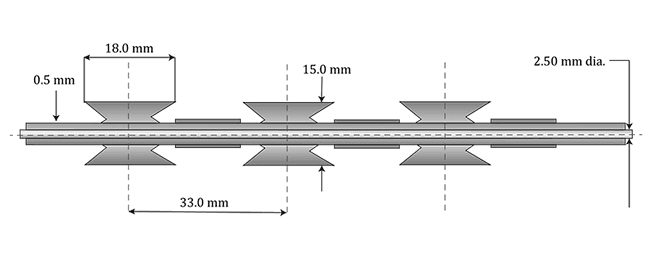

| BTO-18 |  | 0.5 ± 0.05 | 18 ± 1 | 15 ± 1 | 33 ± 1 | 2.5 ± 0.1 |

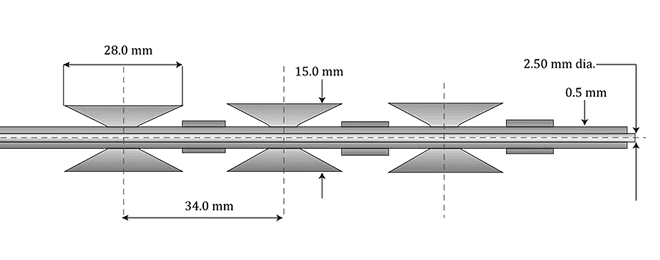

| BTO-28 |  | 0.5 ± 0.05 | 28 ± 1 | 15 ± 1 | 45 ± 1 | 2.5 ± 0.1 |

Coil Loop Specifications

| Outer Diameter | Loops | Extended Length | Blade Type | Note |

| 300 mm | 33 | 4–6 m | CBT- 60, 65 | Single coil |

| 450 mm | 33 | 7–8 m | CBT- 60, 65 | Single coil |

| 500 mm | 56 | 12–13 m | CBT- 60, 65 | Single coil |

| 700 mm | 56 | 13–14 m | CBT- 60, 65 | Single coil |

| 960 mm | 56 | 14–15 m | CBT- 60, 65 | Single coil |

| 450 mm | 56 | 8–9 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 500 mm | 56 | 9–10 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 600 mm | 56 | 10–11 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 700 mm | 56 | 10–12 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 800 mm | 56 | 11–13 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 900 mm | 56 | 12–14 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 980 mm | 56 | 14–16 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |